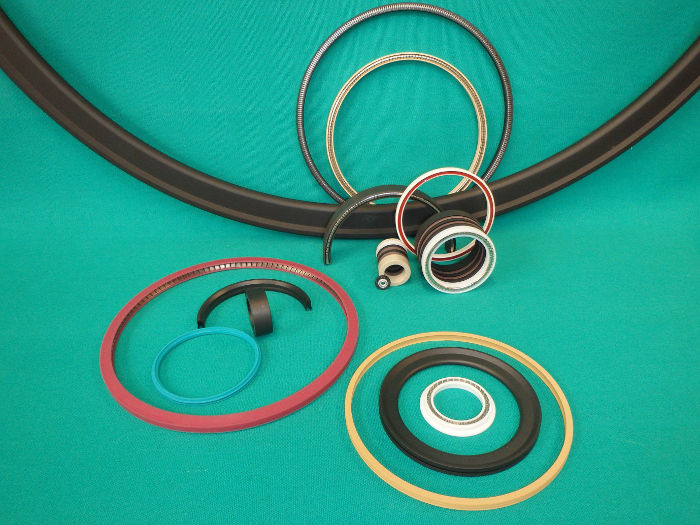

MANUFACTURERS OF PTFE SPRING ENERGISED SEALS

Material Selection

SE Seals

Rotary Seals

Hydraulic Seals

Metal Seals

We’re Moving! Click here for details

Moontown Limited is a UK manufacturer of energised PTFE sealing systems. We pride ourselves on the ability to take products ‘from powder to part’ allowing total control of the manufacturing process.

We have a wide range of standard products complimented by a fully bespoke design service.

Typically our sealing systems see use in the following fields;

- Oil and Gas Industry

- Petrochemical Processing/Handling

- Fuel Control and Engine Bleed Systems

- Off Highway and Construction Equipment

- Machine Tools

- Semiconductor Industry

- Food and Drugs

- Medical and Laboratory Equipment

- Pumps, Valves and Compressors

- Renewable Energy

- Marine Industry

- Motorsport

Moontown products include

PTFE Seals.

- Resilient PTFE seals

- Spring energized PTFE seals

- PTFE seals for Food and Drug service

- PTFE Seals for oil and gas Industry

- PTFE seals for hydraulic service

- PTFE seals for cryogenic service

- PTFE seals for rotary service

- Flange seals

- Low friction seals

- High pressure PTFE seals

- PTFE seals for the chemical industry

- PTFE axial and radial seals

- Special section PTFE seals.

Metal Seals

- Metal O seals

- Metal C seals

- Metal E seals

- Spring energized-resilient metal seals

- Cryogenic metal seals

- High temperature metal seals

- High pressure metal seals

- Metal seals for high vacuum

- Oil and gas Industry metal seals

- Metal seals for the chemical industry

- Metal flange seals

- Special metal seals.

Approved Materials

Moontown currently hold approval to both NORSOK M-710 Rev 2 and API 6A for 8 of our widely used materials. For more information please see the Approved Materials page.